Piles without bentonite slurry or a polymer

For environmental reasons, the use of bentonite slurry to stabilise pile excavation walls has become somewhat questionable. Although the use of polymers has been largely developed, it might not be the solution for all situations, mainly due to the type and degree of the soil aggressiveness and the water contained in its pore spaces.

As a result, SPFE has developed piles for its project Bridge Over the Tejo River in Carregado, Portugal, that are fully encased and recovered without the use of bentonite slurry or a polymer.

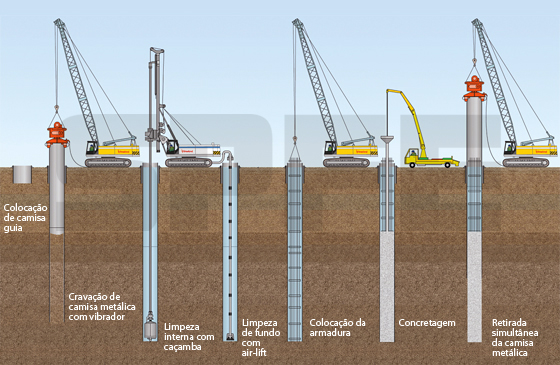

Implementation Methodology

a) Drill and casing guide are positioned;

b) Spiking of the casing guide, using a high power vibrator to the designed depth. Depending on the length of the pile, casing may be spiked into various welded segments. Before welding each new element, internal cleansing is done using the drill while keeping the reinforcement full of water;

c) Upon reaching the project depth, 'dirty' water is replaced by clean water and the lower end is cleaned using the 'air-lift';

d) Reinforcement cage placed in modules, according to its length;

e) Underwater concreting, with simultaneous removal of the casing, which also occurs in segments.

Worthy of mention is that the methodology shown below may present a variation when the excavation is only partially reinforced with casing (for example, during an initial stage, where there is a thick layer of soft clay). In this case, the use of bentonite slurry or the polymer will be a requirement to stabilise the portion of the excavation with no casing.

Large diameter Bored Pile

Large diameter Bored Pile Slurry Wall

Slurry Wall Diaphragm Pile

Diaphragm Pile CFA Pile

CFA Pile Root Pilles

Root Pilles Jet Grouting

Jet Grouting Environmental Geotechnics

Environmental Geotechnics Soil improvement

Soil improvement Cutter Soil Mixing

Cutter Soil Mixing Hydromill

Hydromill Tiebacks

Tiebacks Massive treatment

Massive treatment Static load tests

Static load tests Pt

Pt